TRANSPORTATION - AVIATION - EVTOL AIRCRAFT, RAIL, TRUCKING, AUTOMOTIVE, NON ROAD MOBILITY MACHINES (NRMM), MARINE - COMMERCIAL & LEISURE

Our more than 25 years in the Transportation market began with a tire-pressure monitoring battery manufactured by Maxell, the global leader in high-temperature lithium coin cells that meet Department of Transportation specifications. From there, JLM technologies expanded to primary electrification for the last five years related around lithium -ion and sodium-ion battery cells, modules, and even raw materials ( anode, cathode ), Battery Management Systems for Fast Charging, and EV Charging Stations.

We typically select proven consumer electronics technology to apply to the automotive industry. By choosing technology that only requires modification, we can reduce the engineering cycle in half – often cutting the time to 18 months from 36 months. Our proven strategy is to work with advanced engineering teams on new technology roadmaps and execute a fast-track development program.

Today, we work with OEMs in North America, Europe, Japan & S. Korea. Also, we have potent partnerships with Germany’s top automotive / truck manufacturers Tier 1 & 2 suppliers Volkswagen-Audi-Porsche, BMW & Daimler, Bosch & Continental. One new developing niche has been Marine OEMs creating the world’s adoption of electric boats.

How Electrification is Powering a New Era of Transportation

It was 134 years ago when a patent for the world’s first gas-powered automobile was issued to Carl Benz after he walked into the Imperial Patent Office in Berlin, Germany, on Jan. 29, 1886.

Even though Benz, and several other early automotive inventors, picked the right powertrain solution from many options at the time – one that has proven to be very effective for more than a century – it still took decades before the internal combustion engine (ICE), gas-powered cars were widely adopted in the U.S. and other countries.

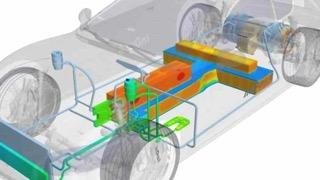

A similar transition is happening today, from ICE-driven vehicles to electrified propulsion systems for cars and trucks. There may be scepticism, even frustration, that the move to hybrids and battery electric vehicles hasn’t happened faster or reached higher volumes since the modern-day electrification movement began in the 1990s.

For example, while battery companies are tweaking cell design and chemistries, we’re improving integrated power modules and battery management systems to more efficiently package components and manage power – further boosting range and shortening charge times, eroding the advantages offered by internal combustion engines for longer road trips and quicker stops to fuel up.

Aviation & Marine

We are transitioning electric aviation and marine power. Electric aeroplanes will not likelybe used until battery technologies improve, as planes remain impacted by weight and power problems. Marine commercial & leisure have moved primarily out of Europe as Norway is leading the world.

New battery technologies can make electric vertical take-off and landing aircraft (eVTOLs) and electric aviation a more realistic mode of transportation. As we shave off battery weight, we can enable them to go the distance. Opening up airspace to eVTOLs will require batteries to be able to undergo high-speed charging. Like the fossil fuel-powered planes of today, electric planes will need to recharge fast to allow for more flights (which equals more customers). Transitioning electric aviation from a novelty to actual functionality is what we’ve been waiting for to reduce the emissions of every flight radically.

Electric Marine Powertrain Technology Gets the Backing of a $2 Billion Powerhouse

Already, a handful of established manufacturers are following suit, investing heavily in the upgrade. And for a clear reason, the economics speak for themselves. The already $18.9 billion general recreational boating industry is growing at a 6.5% clip – expecting to reach $25.9 billion by 2028.

EV Market

E sportscars

AstonMartin, Bugatti, Corvette, Ferrari, Faraday, Jaguar, Lamborghini, Lucid, Lotus, McLaren Pagani, Polestar, Maserati, Porsche, Rimac Automobili

e motorcycle

BMW, Ducati, Live (Harley-Davidson), Lighting Motors, KTM, Razor, Verge, (big 4 Japan: Honda, Yamaha, Suzuki, Kawasaki) and Zero

e powerboats

E mining / construction / AG

E refuse

e cement

rail

EVTROL - AEROSPACE

firms under agreement

NEXTECH batteries

Carson City, Nevada 89706

Founded in 2016 to leverage Li-S energy storage technology developed at Lawrence Livermore Laboratories into production. The corporation is venture-capital backed and privately funded, conducting internal research and development programs to enable LiS chemistry through production. With the successful implementation of NexTech’s current Li-S chemistry, the company is under contract with the California State Energy Resources Conservation and Development Commission to design and demonstrate a grid-integrated battery energy storage system that utilises the unique Li-S battery cell at a utility-scale. In addition, it designs, develops, and fabricates a compatible battery management system to demonstrate and verify the performance data. The project scales up the Li-S battery module system into a grid-integrated system to install, commission, monitor, and collect performance data.

TECHNICAL SPECS

BUSINESS PLAN

PROPOSITION

NEXTECH MANAGEMENT DECK

PURE HYDROGEN CORPORATION LIMITED

119 Willoughby Road Crows Nest NSW 2065 Australia

Pure Hydrogen (ASX: PH2) is building a network of clean hydrogen production facilities across Australia while supplying the market with multiple fuel cell products such as speciality trucks, generators, MG Electrolyzers and Energy Storage.

Turquoise Hydrogen is produced through a process known as methane pyrolysis, using natural gas and just 12.5% of the electricity required for electrolysis

-Green Hydrogen is produced by electrolysis, using water and renewable electricity.Renewable energy is used to power an electrolyzer that splits hydrogen from water molecules. This process creates "green hydrogen," which results in no carbon emissions. Green and blue are two colors used to classify hydrogen by its production method and emissions profile.

Pure Hydrogen and its partners have launched a range of hydrogen fuel cell power generation units that can be used for back-up power or continuous electricity supply for industries/communities dependent on diesel generators ( In the MW range )